Carbon Capture & Storage

Klimagevinsten er betydelig

Hos Frichs Pyrolysis arbejder vi med Carbon Capture, Utilization, and Storage (CCUS) gennem pyrolyseteknologi. CCUS hjælper med at reducere CO2-udledningen og bekæmpe klimaforandringer ved at fange, genbruge og lagre drivhusgasser.

Ved at anvende pyrolyseteknologi kan vi omdanne restprodukter fra landbruget, fødevareaffald og andre biomasser til grøn energi i form af pyrolysegas og binde CO2 i biokul.

For at illustrere, hvis de 2 millioner ton halm, der årligt nedpløjes i Danmark, i stedet blev behandlet ved hjælp af pyrolyse, ville det medføre:

- En fangst og lagring på 1,32 mio. ton CO2 om året i form af biokul

- 4,75 mio. MWh grøn energi i form af pyrolysegas

Det svarer til godt 100.000 danskeres CO2e-udledning pr. år og godt 2,9 mio. danskeres gennemsnitlige el-forbrug pr. år. Vi kombinerer altså grøn energiproduktion med CO2-binding og -lagring.

*Der kommer en løbende strøm af nye ord og begreber med relation til klimateknologier – ét af dem er CCUS, som kort fortalt betyder, at man binder CO2 fra atmosfæren, at den bliver anvendt – og lagret, således at CO2 rent faktisk tages ud af omløb.

Frichs Pyrolysis Nyheder

Seneste Nyheder

Pyrolyse

Hvad er pyrolyse

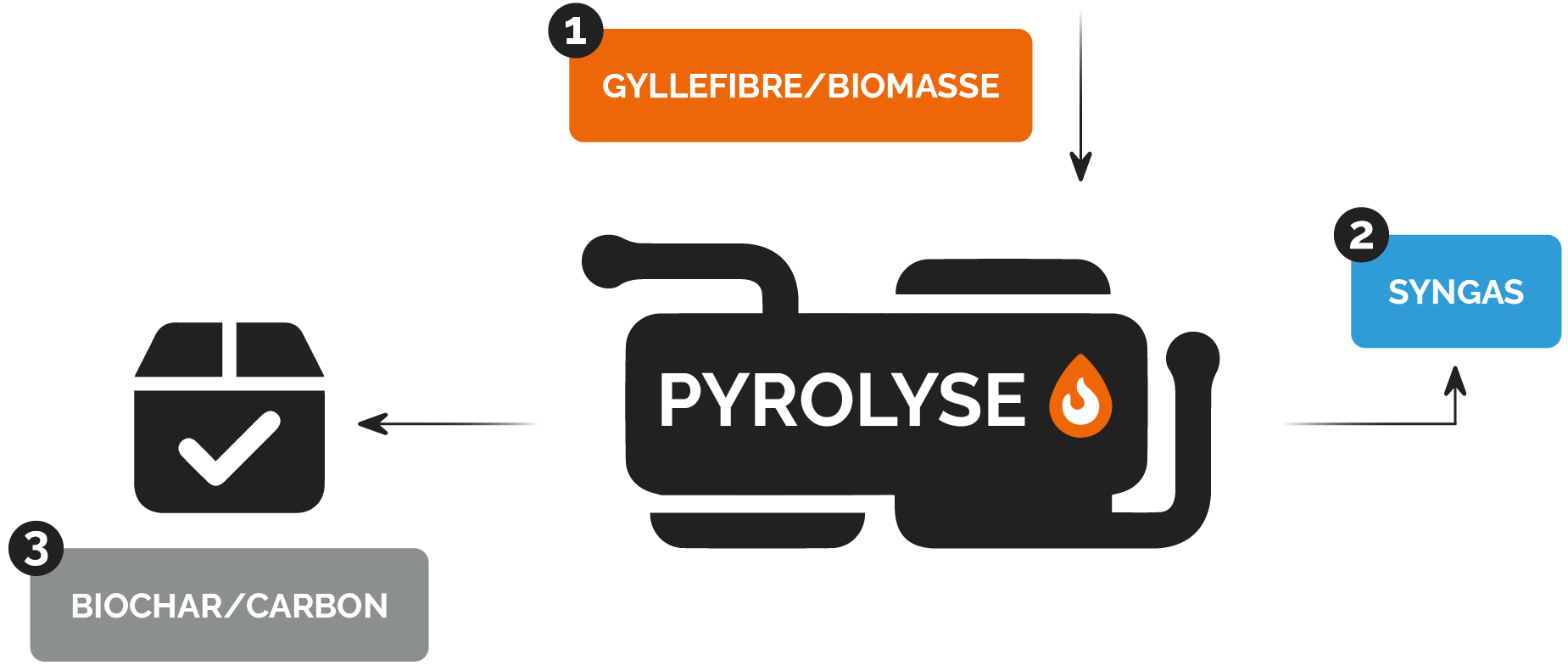

Pyrolyse er en proces, hvor man

- Varmer en brændbar biomasse så højt op, at

- gassen i biomassen frigives. Under normale forhold i fri luft, vil ilten i luften få den varme gas til at brænde – det er f.eks. det der sker, når man stryger en tændstik. I pyrolyseprocessen er der ikke ilt til stede, og derfor brænder gassen ikke. Gassen kan tages ud af anlægget, renses og køles ned, så den kan lagres.

- Samtidig danner pyrolyseprocessen biokul, der indeholder kulstof, som populært sagt er bundet CO2 samt de mineraler der var til stede i biomassen før pyrolysebehandling.

Det er den korte fortælling om effekten af flash-pyrolyse samt processen – hele værdikæden har et større antal delelementer – disse er beskrevet yderligere under de følgende overskrifter.

Klimagevinst

Klimateknologi med mindst fem værdiskabere

Fra stald til CCUS og energi vil processen være

Beskrivelse – proces – fra mark/stald/skov/industri til CCUS og energi

Forbehandling og klargøring

Pyrolyseprocessen

Opbevaring og distribution af biokul

Opbevaring og anvendelse af pyrolysegas

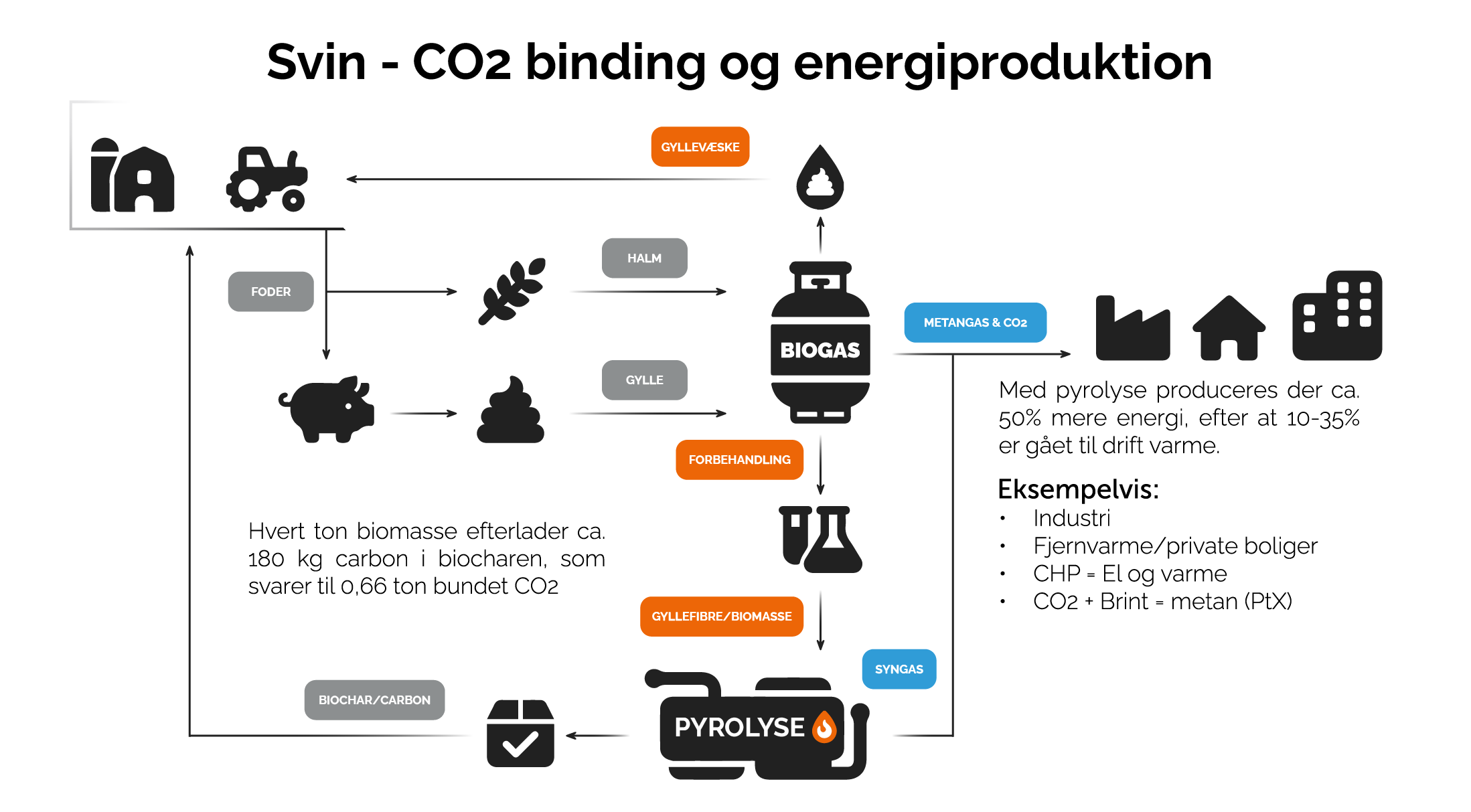

Svinebrug – i samspil med biogas

Eksempel på værdikæde med pyrolyse

Her er vist et eksempel på værdikæden med i samspil med biogas. I princippet kan man forestille sig mange kombinationer med forskellige biomasser med og uden biogas. Kernen er, at der laves CCUS og at der produceres grøn energi. Hvad syngassen bruges til vil afhænge af den aktuelle lokale infrastruktur.

Sættes pyrolyse i forlængelse af et biogasanlæg, forøges netto energiproduktionen med ca. 50%

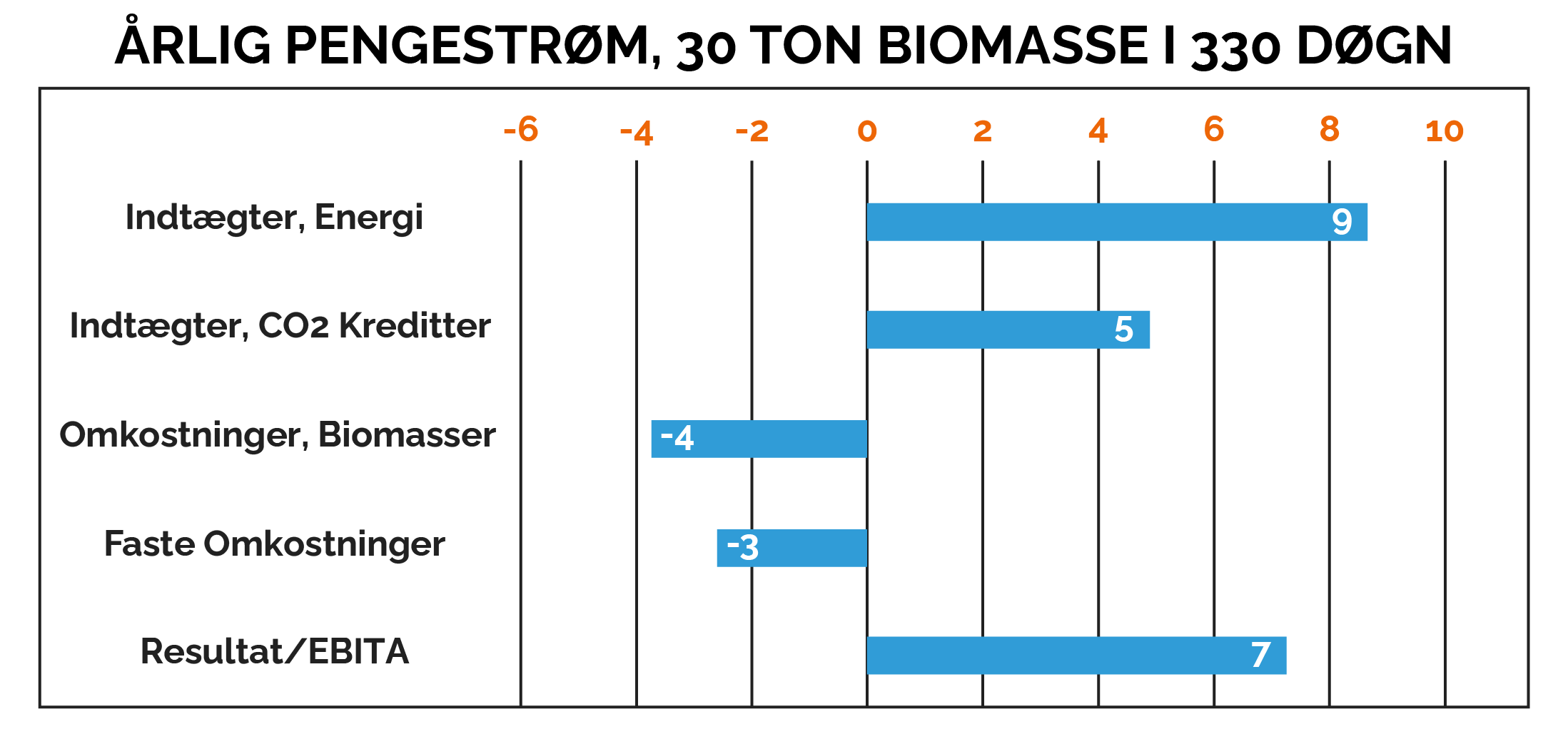

Økonomi i Pyrolyse

Der er god økonomi i pyrolyse fra Frichs Pyrolysis

Pengestrøm – antagelser

- Der pyrolyseres 30 ton biomasse pr. døgn over 330 produktionsdage pr. år – således at der pyrolyseres 9.900 ton biomasse årligt.

- Biomassen er et mix af gyllefibre og halm, der er uafgasset

- Energi er værdisat til 0,35 DKK pr. kWh

- CO2 er værdisat til 750 DKK pr. ton CO2

- Indkøbte/anvendte biomasser er værdisat til 750 DKK pr. ton

- Certifikater fra grøn energi og værdi af biokul som jordforbedring er IKKE med.